History

The first windmills appeared on the Eurasian continent in the 9th and 10th centuries, in the western part of later Afghanistan. Windmills with a horizontal driving axis were an independent European invention, originating from the late 12th century in the North Sea regions: Normandy, Flanders, Brittany and England, from where they spread throughout Northern and Western Europe in the 13th century.

Windmills appeared on Polish lands at the beginning of the 14th century, more than a hundred years later than water mills, which were already in operation in the middle of the 12th century. Already in the 13th century functioning of windmills was recorded in documents in Western Pomerania (a document of Prince Wisław of Rugia for the monastery in Biały Buk from 1271 and a document for the Cistercian nunnery from Szczecin from 1289). Then, the documents recorded windmills in Wielkopolska and Kuyavia (document of Mikołaj, palatine of Kalisz from 1303 for Kobylin). In the fifteenth century, the construction of windmills spread, but mainly in the lands of northern Poland. In addition, their importance was still less than that of watermills.

The flourishing of windmills in Poland took place only in the 16th century, probably due to the increase in population and the increase in demand for flour and groats, especially in urban centers where the construction of a large number of water mills was impossible. On the other hand, it was relatively simple to place windmills in the suburbs or in the close vicinity of towns, especially in large open areas of Wielkopolska. The popularity of windmills lasted until the 18th century, and they were an element of the Polish landscape until the 19th century.

Architecture

The location of the windmill depended on the weather conditions prevailing in a particular place, i.e. the strength and direction of winds, the number of windy days and the topography. Most often they were placed on hills, away from buildings and forests, in the largest possible open space or near large water reservoirs. In flat areas, artificial mounds were built or stone and brick foundations were erected on which a windmill was placed. All these measures were aimed at enabling the maximum use of the wind as a driving force. Convenient access roads leading to the mill were also marked out and hardened, so that the horse-drawn vehicles bringing the grain and the flour away could freely reach the windmill itself.

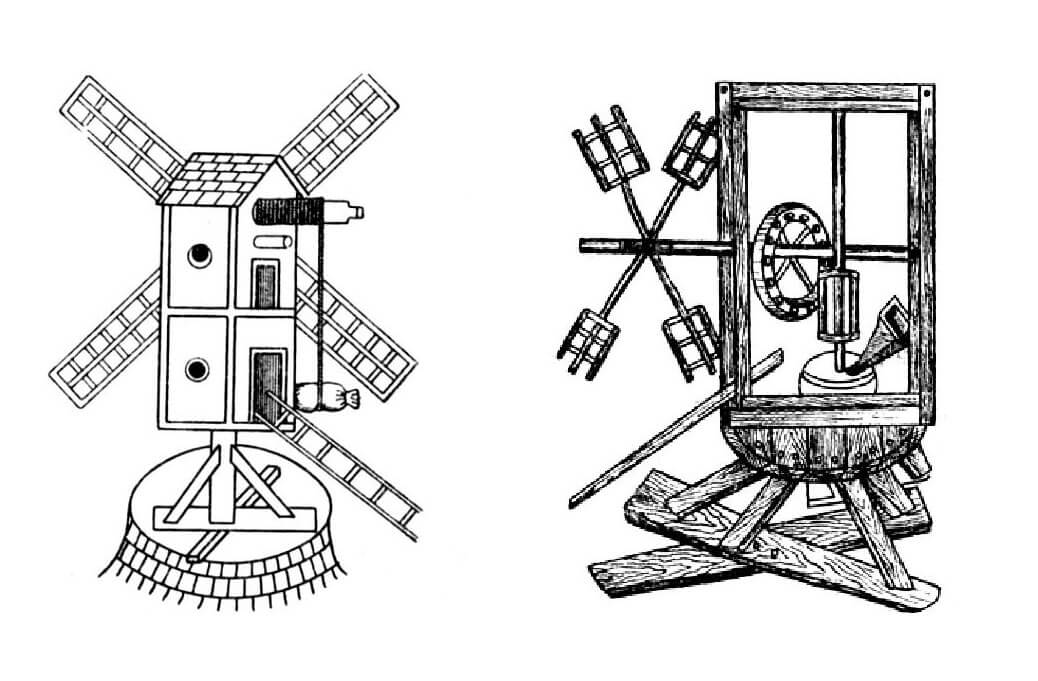

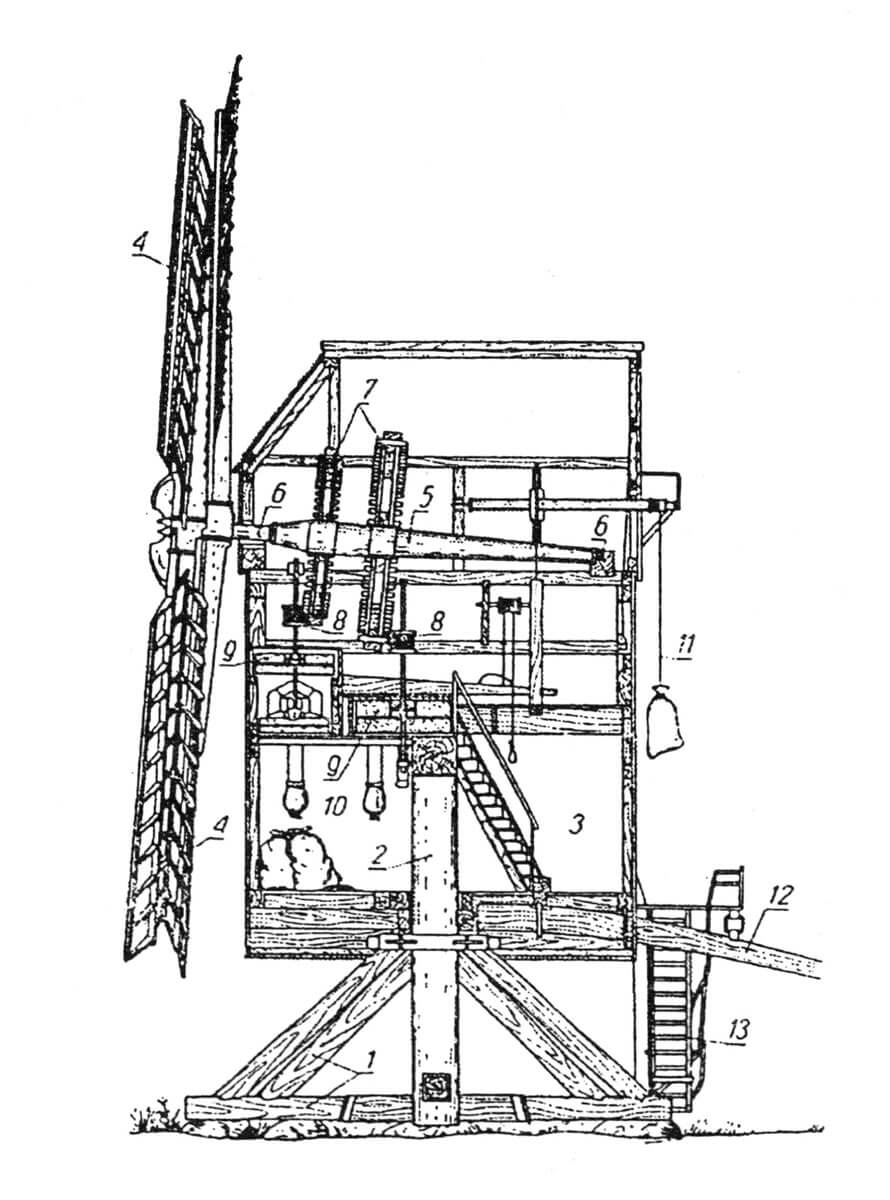

The post mills were made of wood forming a frame, and from the outside were covered with shingles or boarded, which resulted in a figure similar to a truncated pyramid and a height of 7 to 14 meters. The frame consisted of load-bearing elements and stiffening braces and struts. In this way, divisions of walls were created into smaller fields with a span that was easier to cover with planks or shingles. Horizontal elements were erected alternately, i.e. at right angles, successively in successive storeys. In this way, the stability of the building was ensured. The structure was carefully arranged from the bottom up in the entire rotating part of the windmill, with ceiling beams on the first floor and a massive beam called “mącznica” on the second floor, supporting the entire upper part of the windmill (one of the few parts that was given decorative forms – ornaments, mouldings, carved sentences, initials). Roofs and eaves were the culmination of the windmills.

The post mills had three floors. The lowest one was occupied by the stabilizing structure of the trestle, consisting of two intersecting foundations with a maximum length of about 6.5 meters, with four struts attached to them, supporting a central pole (“sztember”). This pole was a vertical axis around which the entire windmill structure was rotated, so that its propellers (also known as wings) could take a suitable position in relation to the driving wind. The two upper floors were dedicated to the production of flour. In the middle one there were millstones with a basket. In the attic there was a place for a shaft converting wind energy into the work of mechanisms. A transmission wheel and a smaller wheel were mounted on the shaft, moving the millstone, transmitting the rotary motion of the horizontal shaft to the vertical axis of the millstone. After grinding, the grain was transported to the container with the sifter, and then, in the form of flour or groats, the finished product left the windmill and was loaded onto carts. The post mill was able to grind from 60 to 90 tons of grain on 120-150 windy days a year.

Four wings had a frame structure, which made it possible to adjust the force of wind pressure on the blades by putting on or taking off linen aprons. In the case of light gusts, the entire surface of the wings was covered to “catch” more wind, and during a storm, the sheets were removed to protect the wings from damage. In extreme conditions, the rotation of the wings was stopped, by blocking the transmission wheel. The rotation of the wings was also controlled by putting wooden staves on the propellers.

The shingled walls initially did not extend all the way to the ground because of their cost and weight. Probably this sight gave rise to fairy tales about a “a witch hut”. The stories may have meant to discourage children from approaching the windmill, as its wings were the cause of many fatal accidents. The entrances to the windmills were placed in the rear walls, opposite to the working wings. On the second floor, the so-called Grain Doors, through which grain to be milled was brought in, accessed by ladders or steps. On the first floor, there was a Flour Door, through which the finished product was carried out, but sometimes only a simple hatch or a shutter created in the entrance door was placed in the back wall. Inside, vertical communication was probably provided by wooden single-flight stairs. Grain, due to its heavy weight, could be moved inside the windmill using ropes, pulleys and winches mounted on the rear wall. The interior lighting was quite poor. The sun shone through the open door, or through the round or four-sided, small openings with the diameter of a human head, placed in the side walls and, if necessary, covered with boards.

The moving part of the post mill with wings was properly adjusted to the wind by means of the so-called tail, i.e. a diagonal drawbar, the outer section of which was on a suitable support. At the end of the drawbar, a chain could be attached, which was rolled on a vertical turnstile, causing a slow rotation of the post. Horses were also sometimes harnessed to the drawbar. The range of the drawbar clearly marked the boundaries of the windmill in relation to the neighboring agricultural land (provided it was located on developed land), which had to be at least 10-12 meters away. A safe distance was also enforced by wings, thanks to which the windmill area was a figure similar to a circle with a diameter of at least 25 meters.

Current state

In the area of the villages of Moraczewo and Lednogóra, since the 1960s, there have been three 19th-century post windmills. They were moved from Swadzim, Sołeczno and Sędziwojewo as part of the development of the medieval Piast Trail. All of them were built at the beginning of the 19th century. Despite the late date of construction, I placed them on the website because post mills appeared in Poland in the 14th century and survived without major structural changes until the second half of the 20th century. In the nearby Museum of the First Piasts in Lednica (Muzeum Pierwszych Piastów w Lednicy), there is the oldest windmill in Poland from 1585, moved from Gryżyna near Kościan. It is located near the ferry crossing to Ostrów Lednicki.

bibliography:

Dąmbska E., Śmiałowski R., Budownictwo drewniane i młyny wietrzne na Ziemi Lubuskiej, Poznań-Zielona Góra 1963.

Jankowski J., Wiatraki Wielkopolski, Leszno 2006.

Talaga W., Dawne budownictwo na Ziemi Jarocińskiej. Na przykładzie historii karczm, wiatraków, młynów wodnych i ich rozmieszczenia, Jarocin 2017.

Tłoczek I., Polskie budownictwo drewniane, Warszawa 1980.

Wilke Z., Dzieje młynarstwa, Szreniawa 1997.

Wyrwa A.M., Dzieło człowieka pod opieką Boga. Wiatrak z Gryżyny: najstarszy zachowany młyn wietrzny w Polsce i jego symboliczne przesłanie. Wprowadzenie do szerszych rozważań, “Studia Lednickie”, XVII (2018).